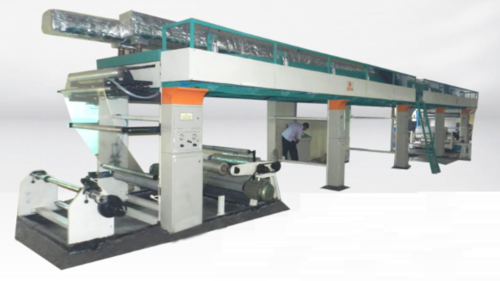

BOPP Tape Coating Plant

BOPP Tape Coating Plant Specification

- Type

- BOPP Tape Coating Plant

- Material

- Mild Steel / Stainless Steel

- Capacity

- 400-2200 mm (Web Width)

- Printing Speed

- 40 - 120 m/min

- Computerized

- Yes

- Automatic Grade

- Automatic

- Plate Type

- Coating Roller

- Print Direction

- Unidirectional

- Ink Type

- Not Applicable (Coating only)

- Control System

- PLC Based with HMI

- Working Temperature

- Up to 200C

- Power

- 50-120 kW

- Size

- Customizable as per Requirement

- Width

- 400-2200 mm

- Weight (kg)

- 8000 - 30000 kg (Approx)

- Dimension (L*W*H)

- Up to 50m x 5m x 5m

- Unwind/Rewind System

- Auto Tension Control with Edge Guiding

- Operator Panel

- Touch Screen PLC

- Safety Features

- Emergency Stop, Interlock, Overload Protection

- Cooling System

- Chilled Roll/Cooling Drum

- Application

- BOPP Tape Manufacturing

- Film Material Compatibility

- BOPP, PET, PVC

- Adhesive Applicator

- Precision Coating Head

- Coating Type

- Single or Double Side

- Heating System

- Hot Air Circulation / Electrical

- Power Source

- Electric

- Main Drive Motor

- AC Motor with VFD Control

- Drying System

- Multi-Zone Dryer

- Noise Level

- <85 dB

- Core Inner Diameter

- 76 mm or customized

- Thickness Range

- 12 - 60 microns (BOPP film)

BOPP Tape Coating Plant Trade Information

- FOB Port

- Mundra

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cheque

- Delivery Time

- 45 to 60 Days

- Main Export Market(s)

- Eastern Europe, Western Europe, Middle East, Africa, Asia

- Main Domestic Market

- All India

About BOPP Tape Coating Plant

Offered BOPP Tape Coating Plant is made by using best quality required materials with the help of innovative technology under the supervision of our clients. This item is utilized in the various industries for coating purposes. It is highly admired in the market because of its long shelf life, high quality and hassle free performance. Moreover, we provide this BOPP Tape Coating Plant in different packaging options at rock bottom prices within the promised time frame.

Technical Specifications:

- Web Width 1350 MM

- Coating station constructed of 35 mm Mild Steel Plates.

- Rubber Covered back up rolls, chamber length 60ft, etc.

- AC Control Panel.

- Speed: - 60 meter/ min. (The operating speed is usually influenced by the type and quality of coated adhesive, materials being handled and of course the operators skill)

Advanced Coating Technology

Experience unparalleled coating consistency with a precision applicator and multi-zone drying system. The plant operates with high efficiency through hot air circulation or electrical heating, combined with controlled cooling via chilled drum, ensuring optimal adhesive bonding on both sides of the film.

User-Friendly Automation

Equipped with a touch screen PLC interface, the system offers automated tension and edge guiding for smooth unwind and rewind operations. Complete process monitoring and adjustment are available, minimizing manual intervention and maximizing output quality.

Versatile Material Compatibility

Specially designed for BOPP tape manufacturing, the plant is compatible with multiple film typesBOPP, PET, and PVC. Adjustable settings allow a wide range of thicknesses and web widths, accommodating various market requirements and customized production orders.

FAQs of BOPP Tape Coating Plant:

Q: How does the BOPP Tape Coating Plant enhance tape manufacturing efficiency?

A: The plant automates tape production through PLC-based controls, auto tension systems, and a precision coating head, reducing manual errors, speeding up setup, and consistently delivering high-quality coated tapes at speeds of 40120 m/min.Q: What materials can be processed with this coating plant?

A: This plant is engineered for BOPP film but also accommodates PET and PVC substrates, allowing manufacturers flexibility in producing different adhesive tape types meeting various industry needs.Q: When is it ideal to operate the plant at its maximum web width capacity?

A: Utilizing the full web width (up to 2200 mm) is best when large-scale production runs are needed, optimizing throughput and reducing changeover times for bulk tape manufacturing orders.Q: Where can the BOPP Tape Coating Plant be installed?

A: The plant is suitable for industrial environments and can be installed in manufacturing units, export facilities, or supplier workshops, thanks to its customizable dimensions and adaptable size options.Q: What is the coating process used by this plant?

A: The coating process involves unwinding the BOPP film, precision application of adhesive using a coating roller, drying in multi-zone dryers, and rewinding under controlled tensionall monitored via a touch screen PLC.Q: How does the hot air circulation and multi-zone drying benefit tape production?

A: Hot air circulation ensures uniform heating, while the multi-zone dryer provides progressive drying, improving adhesive curing, film stability, and the final quality of the coated tape.Q: What safety features are integrated in the plant?

A: Operator safety is prioritized with emergency stop buttons, interlock mechanisms, and overload protection, making the plant secure for continuous, high-speed operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Y-RAPHA COATING PLANT Category

Coating Plant

Size : Customized

Weight (kg) : 3500 kg (Approx.)

Dimension (L*W*H) : 4800 x 2000 x 2200 mm

Control System : Other, PLC Based Control Panel

Capacity : Up to 2000 kg/hr

Automatic Grade : Automatic

Send Inquiry

Send Inquiry