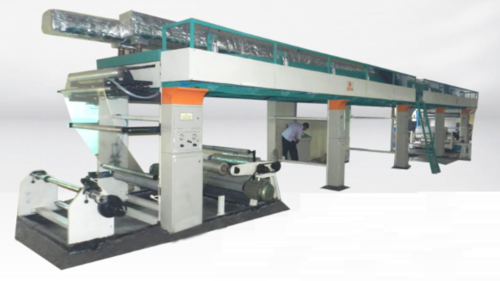

Coating Plant

Coating Plant Specification

- Type

- Coating Plant

- Material

- Mild Steel

- Capacity

- Up to 2000 kg/hr

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Based Control Panel

- Working Temperature

- Up to 250C

- Size

- Customized

- Weight (kg)

- 3500 kg (Approx.)

- Dimension (L*W*H)

- 4800 x 2000 x 2200 mm

Coating Plant Trade Information

- FOB Port

- Mundra

- Payment Terms

- Cash Against Delivery (CAD), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cheque

- Delivery Time

- 45 to 60 Days

- Main Export Market(s)

- Middle East, Western Europe, Africa, Eastern Europe, Asia

- Main Domestic Market

- All India

About Coating Plant

Dry Lamination & Wet Lamination Machines for Solvent Based & Water Based Machines

- Web Widths: 400 to 1250 mm

- Speed: 120 to 225 m.p.m

Salient Features of the Plant:

- Hot Air Temp : 50 1500C

- Heat Source : Hot Air Generator (Optional)

- Exhaust : 3 HP

- Main Drive : Coater / Nip -3 HP, Rewind 5 HP

- AC digital drive for tension controller

- Tendency roll drive AC. With timing pulley

- Maximum speed for solvent base adhesive 225 m.p.m.

- Fully pneumatically lifting tunnels and impressions rollers, Doctor blade, Lay and Rolls

- Chilling roll provided before rewinding

- Comfortable exhaust system for solvent fumes

- Uniform heating system

Precision Performance and Adaptability

This coating plant delivers exceptional adaptability and precision, processing various web materialsfrom delicate films to sturdy fabrics. The PLC-controlled system ensures streamlined, repeatable operation, while temperature control up to 250C handles a wide spectrum of coating jobs, enabling consistent product quality and minimal waste.

Robust Build with Advanced Safety Measures

Constructed from high-grade mild steel and available in powder-coated or stainless steel finishes, this plant offers enduring structural stability. An integrated emergency stop system and adherence to industrial safety standards provide dependable protection for operators and equipment during every production cycle.

Efficient Drying Options and Energy Flexibility

Offering hot air and infrared dryer types, the plant caters to different operational preferences. Choose between electric, gas, or oil-fired heating modes to suit your energy resources and production needs, supporting optimal throughput and energy management for diverse industrial settings.

FAQs of Coating Plant:

Q: How does the Coating Plant ensure high throughput while maintaining quality?

A: The plant uses a computerized system with a PLC-based control panel that automatically manages coating parameters. This maintains consistency even at high capacities of up to 2000 kg/hr, providing uniform quality across paper, film, foil, and fabric materials.Q: What types of drying methods does the plant support, and how do I choose the best one for my material?

A: The plant offers both hot air and infrared drying methods. Hot air is ideal for most web materials requiring even heat application, while infrared suits applications needing rapid surface drying. The choice depends on the materials sensitivity and desired production speed.Q: When should the emergency stop system be used, and how effective is it?

A: The emergency stop system is designed for immediate shutdown in case of equipment malfunction or safety threats. It is highly effective, instantly halting operations to prevent accidents and protect both operators and machinery.Q: Where can this coating plant be installed, and does it fit customized space requirements?

A: The plant can be installed in industrial facilities across India and overseas. As it is available in customized sizes and dimensions, it can be tailored to fit specific production spaces and workflows.Q: What is the process for switching between electric, gas, and oil-fired heating modes?

A: Switching between heating modes involves configuring the energy supply, with the control system accommodating the selected source. This flexibility enables plant operators to optimize energy usage based on availability and cost.Q: How is operational safety maintained during high-temperature coating processes?

A: Safety is maintained with robust emergency stop systems, advanced PLC controls, and construction designed to handle working temperatures of up to 250C. These features collectively mitigate risks associated with high-temperature operations.Q: What are the primary benefits of using this automated, computerized coating plant?

A: The main benefits include enhanced production speed, consistent coating quality, reduced manual intervention, lower operational risk, and the ability to process a wide variety of web materialsall while ensuring energy and safety efficiency.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Y-RAPHA COATING PLANT Category

BOPP Tape Coating Plant

Working Temperature : Up to 200C

Weight (kg) : 8000 30000 kg (Approx)

Type : BOPP Tape Coating Plant

Computerized : Yes

Material : Mild Steel / Stainless Steel

Plate Type : Other, Coating Roller

Send Inquiry

Send Inquiry